Beyond the Visible: Multispectral Imaging for Smarter Packaging & Print Quality Control

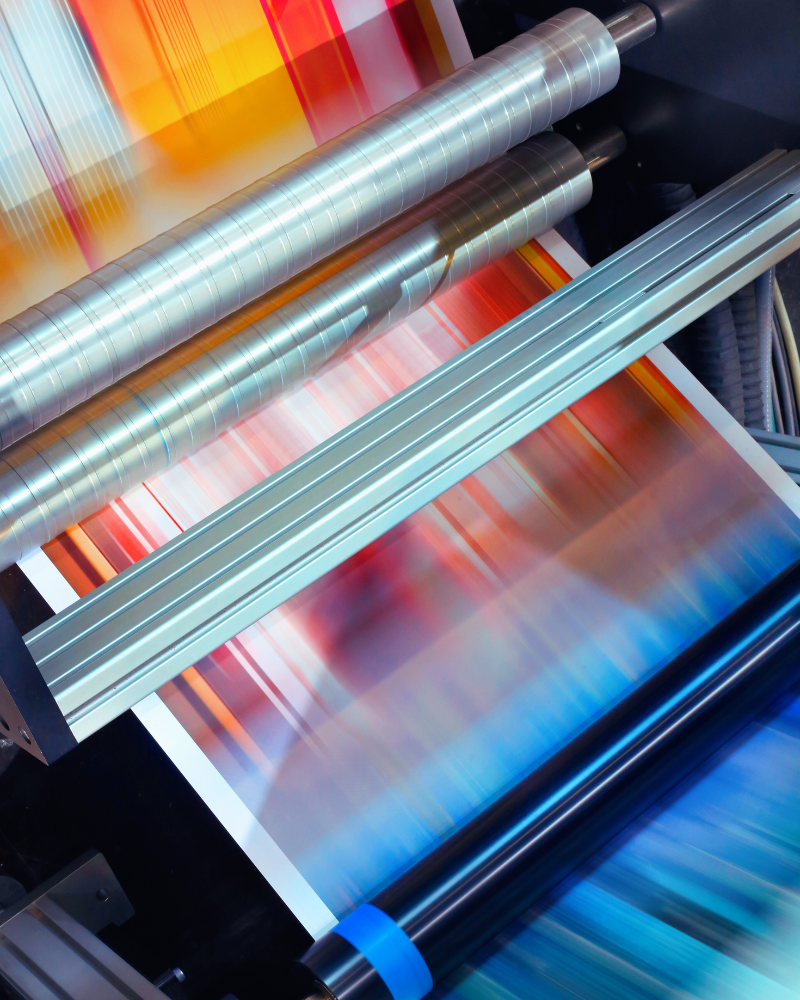

Multispectral imaging is transforming the way manufacturers inspect packaging and printed materials by capturing image data across wavelength bands far beyond what visible cameras can detect. From ultraviolet to infrared, multispectral systems expose hidden contrasts, detect material variations, and reveal defects that defy conventional RGB imaging. The result is higher precision, greater automation, and reliable detection in even the most challenging production environments.

By isolating specific spectral responses, multispectral imaging enables manufacturers to validate inks, adhesives, coatings, labels, and substrates with unprecedented accuracy. Whether inspecting high-speed print lines, ensuring brand integrity, or verifying packaging safety, multispectral solutions provide deeper insight and tighter control across the full production workflow.

Key Benefits of Multispectral Imaging for Packaging & Print Inspection:

- Detects Hidden Defects: Reveals issues such as invisible ink errors, coating inconsistencies, or contaminations that RGB cameras miss.

- Enhances Material Differentiation: Discriminates inks, substrates, and adhesives with similar visual appearance but unique spectral signatures.

- Improves Accuracy & Repeatability: Delivers consistent, quantifiable inspection results not affected by lighting variation or print color shifts.

- Supports High-Speed Production: Enables fast, inline inspection without compromising spectral precision or image quality.

- Strengthens Brand Protection: Validates security features, anti-counterfeit elements, and specialty inks across the full spectrum.

- Cost Effective Spectral Imaging: Collect spectral data only at the bands that matter to you, at a reduced cost compared to hyperspectral technology.

Banknote Inspection

Multispectral imaging brings a new level of confidence to banknote inspection by enabling producers to verify both visible print quality and the many covert security elements built into modern currency.

While traditional RGB systems can assess colour accuracy, surface print, and serial numbers, they fall short when it comes to features designed to deter counterfeiting, such as UV- and IR-reactive inks, watermarks, microtext, and added specialized materials.

By capturing multiple discrete wavelengths simultaneously, multispectral cameras provide a comprehensive view of every banknote as it moves through production, regardless of where it was printed.

Prism-based multi-sensor designs, such as the JAI Fusion and JAI Sweep+ cameras, ensure perfect channel alignment and high-resolution detail, allowing reliable detection of security features and consistent quality control at full production speeds. The result is a powerful, single-system approach that improves inspection accuracy, streamlines processes, and helps safeguard the integrity of currency worldwide.

Article: Bank Note Inspection: Show me the money...in color and multispectral

Ink & Colour Verification

In print production, subtle colour variations and ink mixing issues can compromise brand standards and quality of the final product. Multispectral imaging captures spectral data for each ink layer, even when they appear visibly identical, ensuring precise colour matching and proper ink deposition.

Multispectral imaging enables automated detection of color drift, incorrect ink formulations, and fading, providing confidence that every print meets strict brand guidelines.

Coating & Adhesive Inspection

Many coatings, sealants, and adhesives are transparent in the visible range but highly distinguishable under UV or NIR wavelengths.

Multispectral imaging uncovers uneven application, missing adhesive zones, or contamination beneath films and laminates. This capability helps ensure the integrity of seals, improves packaging durability, and reduces failure rates in downstream processes.